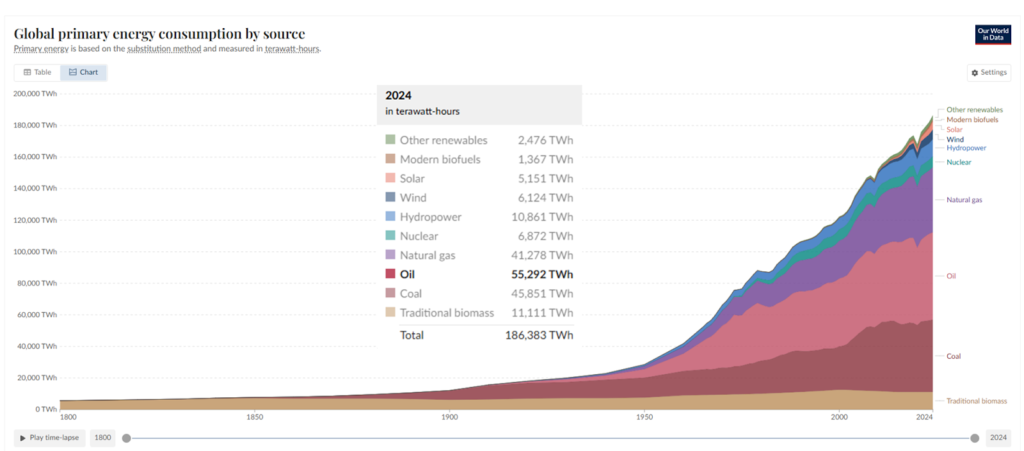

Despite record growth in renewables, oil remains the world’s single largest energy source, fueling transportation, manufacturing and petrochemicals, among others.

In 2024, renewables experienced the highest growth in energy demand, increasing by 11% and electric vehicles made up 22% of new car sales globally. Despite these advances, oil remained the single largest energy source in the global mix, comprising 29.6% (55,232 TWh of 186,383 TWh) of total energy consumption.

For industries under pressure to decarbonise, this reliance poses both a challenge and an opportunity. One overlooked solution? Concentrated Solar Thermal (CST).

CST technology represents a promising pathway to achieving carbon-free steam production in oil refining. As oil refining processes remain significant sources of greenhouse gas emissions, integrating CST may position solar power as an essential ally within the sector.

Why decarbonise oil refining?

Steam generation alone accounts for up to 33% of the total energy consumed in oil refining, powering turbines, heating, and acting as a process medium. Traditionally, this steam is produced using boilers that burn fossil fuels such as refinery gas, natural gas, fuel oil, or coal, which in turn contribute to one-third of a typical refinery’s total greenhouse gas (GHG) emissions.

For the oil and gas industry, which faces mounting scrutiny during the energy transition, decarbonising steam is not a marginal gain. It is a pivotal step towards a more sustainable petrochemical value chain.

Solar integration in practice

My research in northern Colombia, which benefits from abundant solar resources, examined CST deployment in the country’s two main refineries. The findings are promising, indicating that replacing traditional natural gas combustion with CST could reduce emissions by 95%, while also achieving a lower levelised cost of heat (LCOH).

Moreover, CST enables steam production to become independent of natural gas price volatility, protecting operations from potential gas supply disruptions.

Why CST stands out

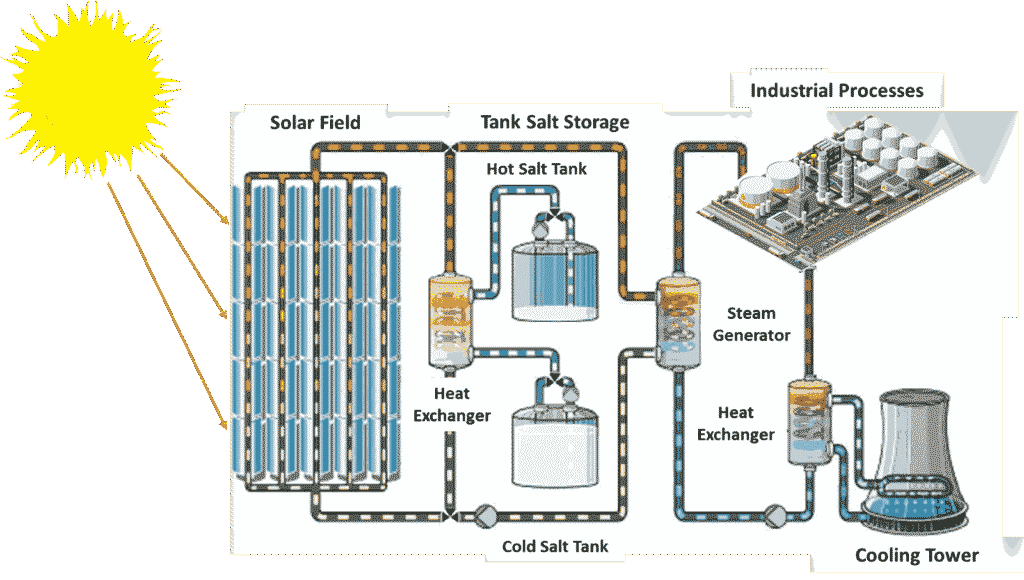

CST systems are advanced renewable energy technologies that harness sunlight to produce high-temperature heat, which can be used for electricity generation and industrial process heating. These systems use large mirrors or reflectors that track the sun’s movement throughout the day, focusing sunlight onto a receiver. The receiver collects and transfers this concentrated heat to a working fluid—such as water or molten salt—which is then used to produce steam for industrial operations.

“Every 90 minutes, enough sunlight strikes Earth’s surface to satisfy our energy needs for a whole year.” -World Economic Forum, 2023.

Compared to other renewable options, CST is particularly well-suited for refinery applications.

A review of 146 international projects from the latest NREL SolarPACES database showed that Parabolic Trough systems have the world’s largest installed capacity for industrial steam generation. They also require the smallest average area per unit of thermal output, making them particularly attractive for decarbonising steam production in oil refining.

Ensuring reliability: competing with gas

An essential question is whether CST can match the 24/7 reliability of gas-fired systems.

Recent advances, highlighted in international projects, suggest that it can. The projects show that using molten salt as both the heat-transfer and storage material offers the best solution. With molten salt thermal storage, CST systems can store enough heat to keep steam production running smoothly for up to 12 hours after sunset. This approach ensures a steady steam supply at the right temperature, maximises the solar capacity factor, and keeps the cost of producing steam affordable.

Molten salts remain stable at higher temperatures than thermal oil, allowing systems to operate at higher temperatures, enhancing the conversion efficiency from thermal energy to steam with smaller energy losses and lower costs. Unlike oil, molten salt doesn’t need extra equipment for heat exchange, which simplifies the system and further reduces capital expenses.

In addition, molten salts are also safe to handle—being non-flammable, non-explosive, and non-toxic—and more affordable to produce than thermal oils since they’re made from common materials like sodium and potassium nitrates, making them a practical choice for large-scale refinery integration

From costs to carbon credits

Besides the potential emissions reduction, replacing natural gas with CST to produce steam has significant operational and economic benefits for refinery owners and shareholders, such as:

- Operational resilience: Removing the risk of refinery operation interruptions by detaching the process from the effects of gas price volatility and supply shortages associated with local production, import, and consumption rates, market, and geopolitical instability.

- Financial advantage: Long-term cost reductions, removing the need to buy natural gas for the steam generation process

- Revenue opportunity: Any natural gas that is no longer needed for steam can be sold to local electricity providers or other industries

- Carbon compliance: Savings through lower carbon taxes or new credits in emerging carbon markets.

For refinery owners and shareholders, CST is not just a sustainability investment, but a financial and strategic one.

A path forward

Ultimately, the path to a sustainable-energy future demands both innovation and courage. There are no silver bullets, and there is no one-size-fits-all, but when bridging the gap between traditional energy and renewables, unprecedented potential can be unlocked.

In this defining moment, every effort matters, and every bold idea brings us closer to a world where clean, reliable energy empowers progress and protects our planet for generations yet to come. Let us seize this opportunity, as it is not only possible, but imperative, to reimagine what energy can be.

This article is based on the author’s thesis as part of the MSc in Energy Management at ESCP Business School, which was awarded Best Thesis from the programme.

License and Republishing

The Choice - Republishing rules

We publish under a Creative Commons license with the following characteristics Attribution/Sharealike.

- You may not make any changes to the articles published on our site, except for dates, locations (according to the news, if necessary), and your editorial policy. The content must be reproduced and represented by the licensee as published by The Choice, without any cuts, additions, insertions, reductions, alterations or any other modifications.If changes are planned in the text, they must be made in agreement with the author before publication.

- Please make sure to cite the authors of the articles, ideally at the beginning of your republication.

- It is mandatory to cite The Choice and include a link to its homepage or the URL of thearticle. Insertion of The Choice’s logo is highly recommended.

- The sale of our articles in a separate way, in their entirety or in extracts, is not allowed , but you can publish them on pages including advertisements.

- Please request permission before republishing any of the images or pictures contained in our articles. Some of them are not available for republishing without authorization and payment. Please check the terms available in the image caption. However, it is possible to remove images or pictures used by The Choice or replace them with your own.

- Systematic and/or complete republication of the articles and content available on The Choice is prohibited.

- Republishing The Choice articles on a site whose access is entirely available by payment or by subscription is prohibited.

- For websites where access to digital content is restricted by a paywall, republication of The Choice articles, in their entirety, must be on the open access portion of those sites.

- The Choice reserves the right to enter into separate written agreements for the republication of its articles, under the non-exclusive Creative Commons licenses and with the permission of the authors. Please contact The Choice if you are interested at contact@the-choice.org.

Individual cases

Extracts: It is recommended that after republishing the first few lines or a paragraph of an article, you indicate "The entire article is available on ESCP’s media, The Choice" with a link to the article.

Citations: Citations of articles written by authors from The Choice should include a link to the URL of the authors’ article.

Translations: Translations may be considered modifications under The Choice's Creative Commons license, therefore these are not permitted without the approval of the article's author.

Modifications: Modifications are not permitted under the Creative Commons license of The Choice. However, authors may be contacted for authorization, prior to any publication, where a modification is planned. Without express consent, The Choice is not bound by any changes made to its content when republished.

Authorized connections / copyright assignment forms: Their use is not necessary as long as the republishing rules of this article are respected.

Print: The Choice articles can be republished according to the rules mentioned above, without the need to include the view counter and links in a printed version.

If you choose this option, please send an image of the republished article to The Choice team so that the author can review it.

Podcasts and videos: Videos and podcasts whose copyrights belong to The Choice are also under a Creative Commons license. Therefore, the same republishing rules apply to them.